The Guardian reported that the public concern over the environment reached a record in the UK in 2019. The subject of sustainability is only becoming more and more important for the future. According to the Pew Research Center, a median of seven-in-ten reports that climate change has at least some effect in the area where they live. And so, people start to be more serious about the problem, which inevitably means businesses need to be more serious about it as well.

There is a vast range of solutions out there to make your company more sustainable and environmentally friendly. But have you ever considered that by implementing “circular economics” your company could generate value from the waste you are creating?

In full circle economics, you look beyond the circle in which you take, make, use, and then throw your products away. A circular economy aspires to redefine growth by focusing on positive society-wide benefits. It means gently decoupling economic activity from finite resource consumption to designing waste out of the system. The principal is based on three aspects:

- Design waste and pollution out of the user cycle.

- Keep products and materials in use.

- Regenerate natural systems.

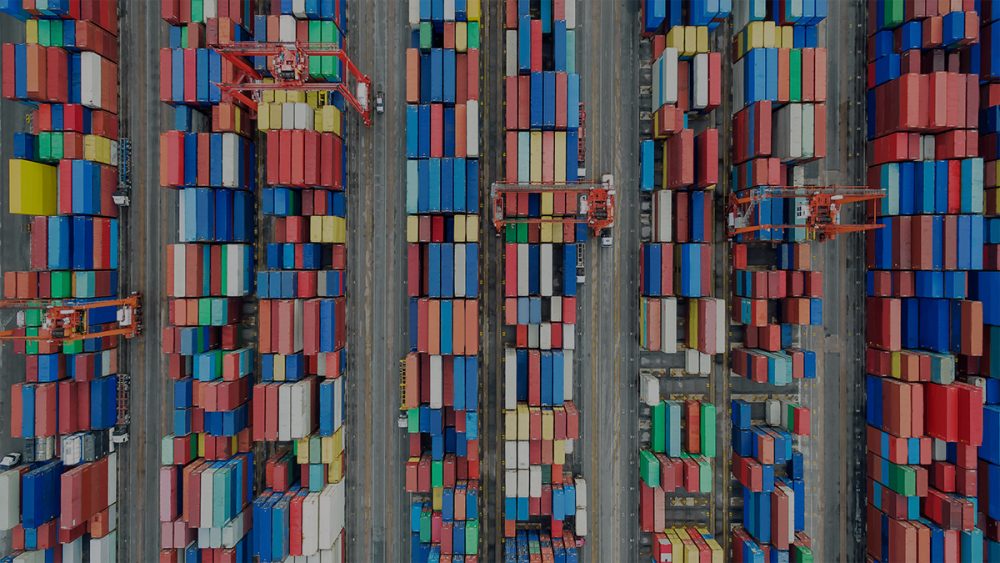

Over the past decades, the circular economy has transformed from a specialist concept to a desirable business strategy. According to Accenture Strategy research, almost all product-based companies say they’ve put in place circular supply chains for recovery and recycling. So, it’s time to come full circle and to transform supply chain operations by building an ecosystem of partners, suppliers, and markets that capitalize on the circulatory system.

So, what are ways you can make the most of circular supply chains?

First, we should shift our focus on driving a circular business model, which means that how our organizations create, offer and deliver value to consumers or other stakeholders should be in line with minimizing ecological and social costs. Preferably to a point where we can reuse products and waste to have zero impact.

Secondly, we should focus on breaking down silos and thirdly, starting the circular economy top-down. To truly make a lasting impact, big corporations should approach the waste problem from the top-down, beginning with the board, going back to the warehouse employees, and maybe even further. Only then can companies truly create a long-lasting, sustainable shift. Lastly, leveraging digital opportunities such as platforms for waste distribution and diversion can keep track of the total supply chain, enabling possibilities such as waste-to-energy creation.

Focus on driving circular business models

By focusing on driving circular business models, you’ll capture the full value of the opportunity. For example, around one-third of all food produced goods go to waste each year, which is 1.3 billion tonnes of food. That costs the global economy $940 billion a year. It takes tremendous vision beyond recycling and prioritizing to take full advantage of this. However, by implementing food waste as fuel, you can get something useful out of the waste, which is then not lost.

Additionally, moving towards a circular economy could deliver benefits such as reducing pressure on the environment, increasing competitiveness, improving the security of the supply of raw materials, stimulating innovation and economic growth, and even creating new jobs. And if you’re wondering what’s in it for your consumers, the answer is simple; they will be provided with more durable and innovative products that will increase the quality of life and even save them money in the long term.

Break down silos

According to Accenture Research, a second vital facet is to break down silos. A circular business model can be disruptive for any organization and they will need strategic collaborations with suppliers and across functions like procurement, supply chain, manufacturing, storage, and marketing. Corporate barriers are why many businesses stop recycling, which can be accomplished through a single functional silo. Companies that will look for opportunities that impact their operating models’ core and seek connections to build with a network of partners will be most successful.

Start the circular economy top-down.

Leadership at the top of the company must create business imperatives, cultural changes, and governance to promote circular objectives (new goals and data).

Being a circular business requires taking traditional metrics such as gross margin and blending them with new metrics to measure the process’s overall effectiveness. That data includes take-back quantities, refurbished or re-used quantities, and resource productivity. By reducing waste and reprocessing it into fuel, the global circular business goals that countries have set for themselves, will be easier to make.

Moreover, top-down decisions can drive significant changes, such as building out a sustainable waste-to-energy supply chain. Inevitably, human activities result in waste. Currently, the higher the material turnover, the more complex and diverse the material produced, the more challenging it is for waste management to reach the goals of “protection of men and environment“.

With prevention and recycling methods, waste-to-energy (WTE) facilities can contribute significantly to reaching the goals of waste management. Connecting with WtE plants can support your decisions about waste and environmental management: for example, the can routinely and cost-effectively supply information about the chemical waste composition and the ratio of biogenic to fossil carbon in MSW and off-gas.

Leverage digital opportunities

Technologies like radio-frequency identification (RFID), electronic logging devices (ELD), and analytics are vital for embedding circularity into the entire operations and company network to increase the ability to track resources and monitor the utilization and waste capacity.

Digital platforms allow companies to understand the value of the materials better and indicate the condition of assets and products. Which, in turn, determines when new services, replacement, and fuel is needed. Gaining these insights is quickly transforming in “table stakes” to engage in a fuller circular economy supply chain.

Final Thoughts

The circular economy is gaining real traction in the supply chains of most major product-based organizations. Industry leaders such as Dell show first-hand the enormous value that can be achieved by making circularity a core aspect of your business strategy. To fully deliver on the value – to the people and planet – circular efforts need to expand beyond the obvious, like recycling and moving into other circular business models.

With digitalization, top-down adjustments to help become a more circular and real effort, we can transform current supply chains into sustainable product-waste-energy supply chains.

Eliminating waste from the industrial chain by re-using materials to the maximum extent possible, even things as food waste, promises production cost savings and less resource dependence. Additionally, one can argue that the benefits aren’t just operational but also strategic and serve as sources for efficiency and innovations. Economies will benefit from substantial material savings and lower supply risks, which will lead to the economy’s long-term resilience.

—————-

At EnMass Energy, we built a one-of-a-kind software platform to support the entire waste-to-energy procurement process, allowing you to implement the circular economy principles into your business model. If you want to learn more about our solution, please get in touch.